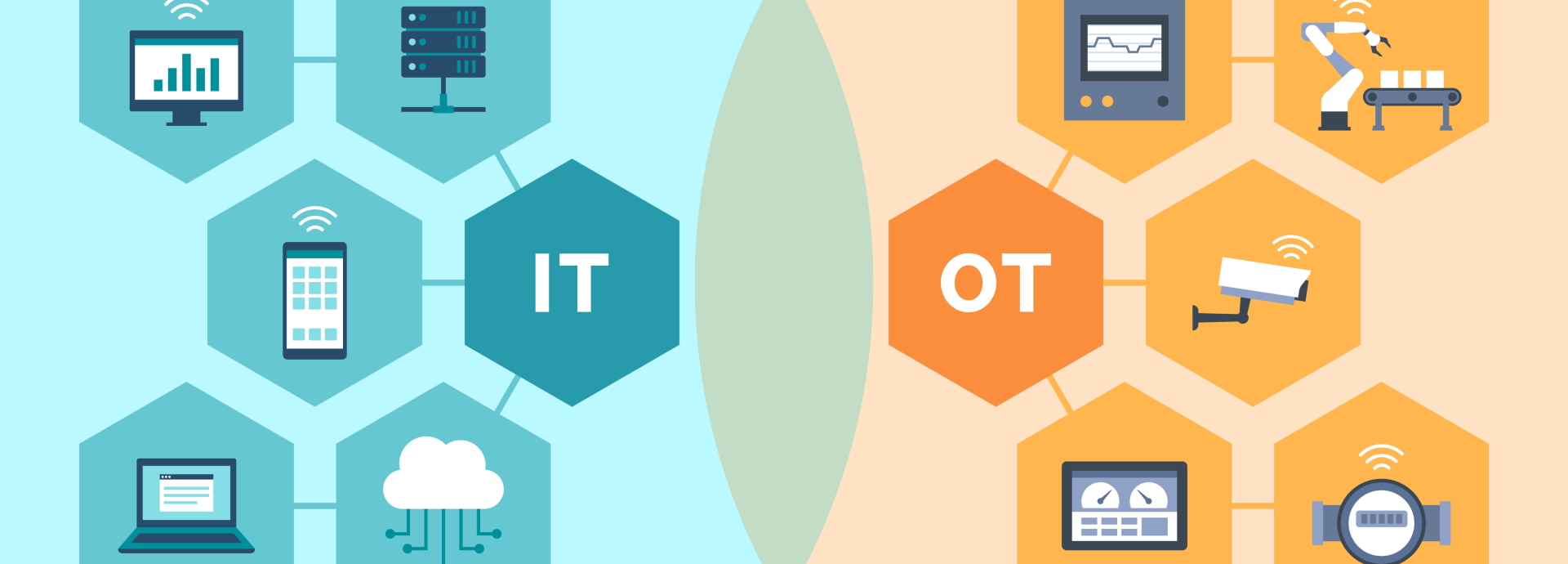

Full OT and IT integration enables uninterrupted data flow and correctly processing all production and business data across all locations.

The goal must be to achieve seamless connection between all the company’s communication networks, systems and applications – from the shop floor to the top floor. This includes software and hardware in use at the various product, machine, line, production, and enterprise levels.

Comprehensive digitalization and successful Industry 4.0 projects cannot be implemented with data silos and isolated applications at the various organizational levels.

Combining machine and organizational data

Data is generated in both the OT and the IT areas – and is the primary intersection of the two. For example, intelligent, technical systems generate enormous machine and plant data at OT level, while customer master and order data, data management and advanced analytics, are located in IT.

Big Data and Advanced Analytics will play a decisive role in the future in terms of operational and strategic decisions for both the production department and the rest of the company. Breaking down data silos and seamlessly integrating systems and data at every level is critical to success.

With the use of data analytics, companies gain transparency and insight into all data sources. Looking comprehensively at all the data from both OT and IT systems, allows decision-makers to view information from all production and organizational systems, to analyze it in a holistic manner, and to drive cross organizational improvement.

Taking advantage of data analytics from OT and IT

IT is responsible for the company’s core systems such as business software, network applications, database applications and general IT management. Software and hardware at the product level, for controlling machines and systems with NC programs, are part of OT.

Complete IT and OT integration means much more than the purely technical integration of software and hardware at the organizational and production level. To increase digitalization as an opportunity for, and driver of business improvement, IT and OT teams must work closely together.

Why is this needed? Obstacles that arise must be solved together. For example, connecting OT device networks with traditional IT data networks can prove to be a major challenge, and implementing a networked, modern production system leads to IT bottlenecks and interruptions to employees. Coordination between the IT department and the employees in the individual production groups should take place at the beginning of a new Industry 4.0 or data modernization project.

Tips for buying a new analytics tool

There are several analytical tools on the market to choose from. The one you select should be equipped with the following functions:

– A step-by-step wizard that shortens the training period for users. The analysis program should be intuitive to allow being used more quickly.

– An integrated out-of-the-box prediction engine, that allows predictive maintenance and demand forecasts to be made without excessive effort.

– Intuitive dashboard creation tools, with drill-down reporting capabilities.

– Natural language query tools

– Executable alerts and notifications for business managers

Plug-and-play solutions for Industry 4.0

Vendor-independent integration and digitization platforms offer modern plug-and-play solutions. They bring together all business processes and systems from IT and OT in a complete and centralized manner. ERP, CRM, PLM, MES, WMS and SCM systems, machines and sensors are then able to communicate smoothly with each other. This alleviates the need to shut down and replace proven systems. The core functions and modules of such a solution include:

- Plug-and-play connectivity of machines and workstations (old and new, manual or automatic).

- Mobile connectivity with a native mobile app that includes push notifications for actionable items and provides production process online visibility.

- Paperless production processes with a tablet application to ensure users have all the information they need to do their jobs.

- An internal messaging system to reduce response time and increase communication.

- A quality, maintenance, task management and Gantt-based planning modules.

- A work-in-process (WIP) inventory control and management module.

Conclusion

Close cooperation between all stakeholders is required to reliably connect IT and OT systems which is key to business success in the digital age. With modern and flexible integration and digitalization platforms, companies can achieve OT and IT convergence – and thus lay the foundation for successful Industry 4.0 projects.

Are you currently planning a new digitalization project? Or do you have further questions about how you can quickly bring OT and IT together in your company? Our team of experts is at your disposal for a non-binding discussion. Contact us!